On Wednesday the 31st of May, the live session of the Circular Industries Talks, titled: Batteries: powering a sustainable future, took place at Leiden University. In this article, we present the speakers, takeaways, and recording of the talks.

#1: The Green Deal – Implications for battery technology by Mark Weijers

In July 2021 the European Commission made an agreement on the Green Deal. This package of measures to enhance the climate has an enormous impact on the activities of European citizens and industries. Electrification of fossil-fuel-using activities is a key aspect of achieving the goals set out in the agreement. There are two emerging demands for batteries during electrification which are set out in this presentation.

Electrification of fossil-fuel-using activities is a key aspect of achieving the goals set out in the European Green Deal.

- For grid batteries which are used to temporarily store electricity from solar or wind, various chemistries can be used which are both sustainable and abundant. Currently the market is dominated by ‘economy of scale’ but a shift to ‘economy of abundance’ is emerging.

- Batteries for the transport sector pose challenges as the typical types of chemistries used are not aligning well with Green Deal goals. Some alternatives exist, but they have a trade-off in terms of performance and therefore there is little incentive to bring them to the market. We are far from a zero carbon emission scenario for the transport sector through electrification, which can only be achieved if the scale of carbon sourcing balances with the carbon used for renewal of end-of-use batteries.

About Mark Weijers

Mark Weijers is PhD candidate with the Materials for Energy Conversion and Storage (MECS) group in the Chemical Engineering department at TU Delft.

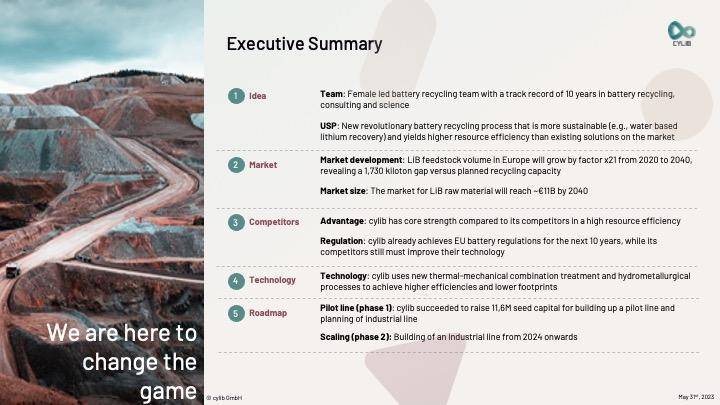

#2: How Cylib realizes circular economy in the mobility sector by Maurice Buschmann

cylib is a start-up for holistic and innovative Lithium-ion battery recycling, starting from discharging to recovery of all components of the battery.

The cylib process enables a true circular economy of lithium-ion batteries and thus contributes to making electromobility sustainable.

LiB feedstock volume in Europe will grow by factor x21 from 2020 to 2040, revealing a 1.730 kiloton gap versus planned recycling capacity. Existing recycling processes do not meet upcoming demands for lithium and graphite recovery. Using mechanical, thermal and hydrometallurgical processes, cylib achieves higher efficiencies and lower footprints, thereby meeting these demands.

About Maurice Buschmann

Maurice Buschmann is Process Engineer at Cylib.

#3 - A vision for a Sustainable Battery Value Chain in 2030 by Lukas Torscht

A 2022 analysis by the McKinsey Battery Insights team projects that the entire lithium-ion (Li-ion) battery chain, from mining through recycling, could grow by over 30 percent annually from 2022 to 2030, when it would reach a value of more than $400 billion and a market size of 4.7 TWh. The majority of the growth comes from battery electric vehicles. In total, at least 120 to 150 new battery factories will need to be built between now and 2030 globally.

For sustainability, the battery industry can only achieve true sustainability if it does not overshoot any of the nine planetary boundaries that the Stockholm Resilience Center defined and quantified.

Battery 2030: resilient, sustainable, and circular

The 2030 outlook for the battery value chain depends on three interdependent elements (Exhibit 12):

- Supply-chain resilience. A resilient battery value chain is one that is regionalized and diversified. We envision that each region will cover over 90 percent of local cell demand, over 80 percent of local active material demand, and over 60 percent of refined materials demand. In addition, by recycling raw materials that are primarily found in one location (such as cobalt), countries can reduce their dependency on others. A recycling target of 80 percent, as recently specified in the EU battery directive, could become an aspiration for 2030 for all regions globally. Across the entire value chain, the industry could contribute to up to 18 million jobs in 2030 by securing existing positions and creating new ones. The number of projected jobs—80 percent higher than in our 2019 report—relates to the higher expected battery demand estimates for 2030.

- A focus on sustainability. Batteries are a major tool in the challenge to decarbonize the mobility sector and other industries—a task that is essential to avoid triggering irreversible climate tipping points. The battery revolution could reduce cumulative greenhouse-gas emissions by up to 70 GtCO2e between 2021 and 2050 in the road transport sector alone. However, the battery industry will need to prioritize the decarbonization of its own industry to maintain its credibility. Our analysis suggests that material and manufacturing emissions could fall 90 percent per kWh battery on the cell level by 2030. Further pack level emissions will mostly depend on achievements in decarbonizing aluminum, steel, and plastic production. The industry could also benefit from setting ambitious improvement targets in the nine planetary boundaries that the Stockholm Resilience Center defined and quantified. These include freshwater change, stratospheric ozone depletion, atmospheric aerosol loading, ocean acidification, biogeochemical flows, novel entities, land-system change, biosphere integrity, and climate change. Significant improvements for all social and governmental challenges mentioned earlier are also necessary to achieve true sustainability.

- Creation of a circular value chain. The battery industry has to move from a linear to a circular value chain—one in which used materials are repaired, reused, or recycled. This transformative approach may also create huge economic potential, with some opportunities already available today (for instance, scrap recycling). A large cross-industry effort and coordination will be needed for stakeholders to achieve the full potential of a circular value chain. Companies could benefit from investigating sustainable and economically viable applications that would increase circularity, or by leveraging technological advances that contribute to this goal.

At a minimum, the battery industry’s growth must help fulfill basic human, product, and economic needs. Important goals include social welfare, inclusive value creation, adherence to international law, emphasis on human rights, creation of durable and performing products, and economic viability for businesses. To create a well-functioning value chain, companies should attempt to avoid any shortcomings in these areas. For sustainability, the battery industry can only achieve true sustainability if it does not overshoot any of the nine planetary boundaries that the Stockholm Resilience Center defined and quantified.

Based on our extensive experience in the global battery value chain, we have identified ten transformational success factors that will pave the way for our 2030 vision in which batteries power a resilient, sustainable, and circular future (Exhibit 13).

About Lukas Torscht

Lukas Torscht is Business Analyst of the Stuttgart Office at McKinsey & Company. Currently, Lukas is on educational leave studying the MSc Industrial Ecology at Leiden University and TU Delft.

#4 - Future material demand for automotive Li-based batteries & EV batteries for short-term storage of renewable energy by Chengjian Xu

Key takeaways:

1. The demand for materials such as lithium, cobalt, and nickel is expected to increase significantly, by a factor of 20-30, between 2020 and 2050. This surge in demand necessitates a substantial expansion of the supply chains for these elements and the exploration of new resources.

2. The adoption of alternative battery chemistries, such as lithium iron phosphate or emerging technologies like lithium-sulfur or lithium-air batteries, would considerably reduce the demand for cobalt and nickel compared to current trends.

Significant advancements in recycling techniques are required to economically recover high-quality battery materials from end-of-life batteries.

3. Although closed-loop recycling plays a relatively minor role, its importance in reducing the need for primary materials is growing. However, significant advancements in recycling techniques are required to economically recover high-quality battery materials from end-of-life batteries.

4. Electric vehicle (EV) batteries have the potential to complement renewable energy generation by providing short-term grid services, further enhancing their overall utility.

5. Our analysis considers both the in-use phase and the end-of-vehicle-life phase, estimating a technical capacity of 32-62 terawatt-hours by 2050 for EV batteries.

6. Globally, low participation rates ranging from 12% to 43% are sufficient to meet the demand for short-term grid storage. If half of the EV batteries at the end of their vehicle life are repurposed for stationary storage, participation rates drop below 10%.

About Chengjian Xu

Chengjian Xu is a postdoctoral researcher in the Photovoltaic Materials and Devices group at TU Delft and a guest researcher in CML at Leiden University.

Curious about the whole story? Listen to Mark Weijers, Maurice Buschmann, Lukas Torscht and Chengjian Xu about the future of sustainable batteries in the Circular Industries talks.

The Circular Industries talks

The goal of the Circular Industries talks is to share knowledge across Leiden, Delft and Erasmus and to complement and deepen the knowledge already available within the Circular Industries Hub. The talks are organized on Wednesday morning from 10:00 to 11:00. The talks are online (Microsoft Teams).

More about the Circular Industries talks